At Premier Products of Racine, we deliver comprehensive sheet metal stamping services, handling everything from concept design to assembly and finishing at highly competitive prices. Sheet metal stamping is a highly customizable manufacturing method, involving numerous options for materials, techniques, and processes.

Sheet Metal Stamping From Premier Products of Racine During the piercing process, punched-out shapes are discarded, with the hole-riddled sheet metal being the desired product.

Rather than keeping the blanks, technicians use the material around the outside of the punched area. This process is often thought of as the opposite of blanking. Stretching of the material is avoided as much as possible to ensure the material stays intact. During the process, tension carefully draws material into a cavity to change its shape. A more complex operation, drawing is used to form deep depressions or vessels. The blank can require additional forming, or it may be the finished component, referred to as a fully finished blank. The piece that results is called a blank. It involves feeding a sheet into a press where a die then cuts out the desired shape. Blanking is the most basic metal stamping process.

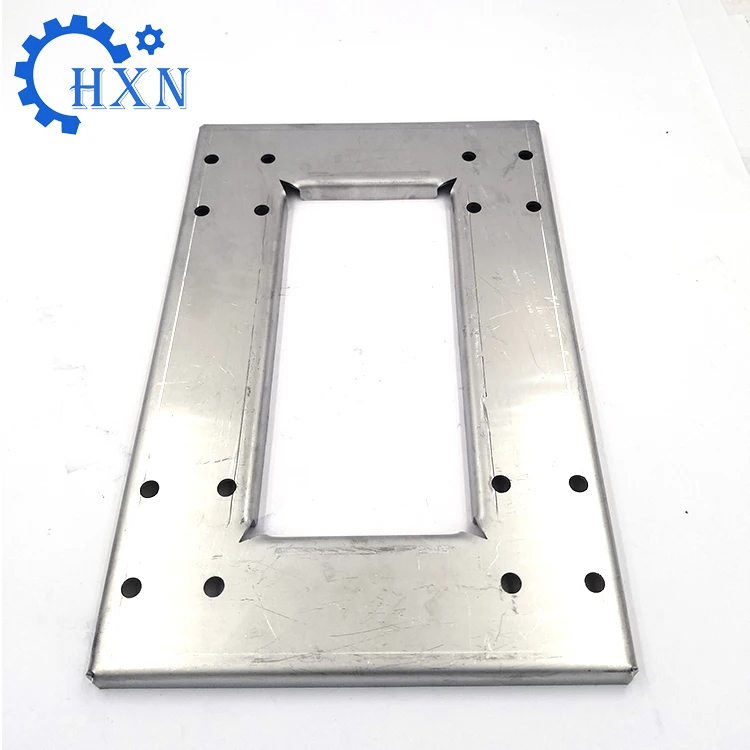

Stamping stainless steel sheet metal series#

By undergoing a series of operations, metal is altered from a simple shape into a highly complex one. There are several methods to accomplish this, depending on design specifications. This is the process of creating a new shape from flat metal by the application of force. The following are some common processes that might occur during the metal stamping process: However, producing any single component can require many steps before it arrives at its final form. There are three components to sheet metal stamping: the sheet metal, the press machine, and the die. Some of the most commonly used materials in sheet metal stamping include: While virtually any type of metal can be stamped, the type used in any given application depends on the desired qualities of the part that’s being created. Pre-galvanized sheet metal is commonly used for creating moisture-resistant components and has the added benefit of being significantly cheaper than aluminum and stainless steel without sacrificing quality. We also offer galvanized sheet metal stamping services. Premier Products of Racine works with a broad range of materials, from aluminum to carbon steel, copper, high-strength steel and more. As a cold-forming technique, sheet metal stamping doesn’t require heat to shape the metal. During the process, metal is fed into a press where a stamping tool, referred to as a die, presses through or into the metal with great force to create the desired shape. Sheet metal stamping is the process of transforming sheets of metal material into a useful component or part. Here, we’ll highlight the sheet metal stamping process and how it works. It is capable of creating high-volume parts while maintaining rigorous tolerance and quality criteria. Sheet metal stamping is a cold-forming manufacturing technique used to create both simple and highly complex designs quickly, accurately, and cost-effectively. Posted by Premier Products of Racine on 9:06 am | Comments Off on Sheet Metal Stamping: What It Is and How It Works

0 kommentar(er)

0 kommentar(er)